Investigating the use of polyethylene pipes in the oil industry

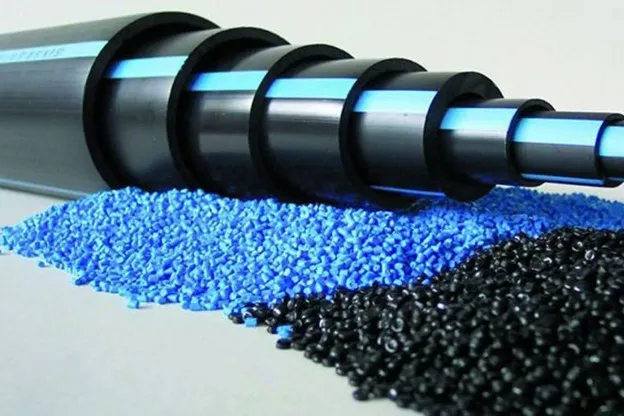

Polyethylene pipes, due to their physical and chemical properties, are one of the most important raw materials for the construction of oil, gas and petrochemical pipelines. Polyethylene pipes have played a key role in the oil industry and oil and gas-related industries in recent decades. In this article, we will examine the reasons for the use of polyethylene pipes in the oil and gas industry.

The applications of polyethylene (PES) pipes in the oil industry include:

- Crude oil transportation: Polyethylene pipes are used to transport crude oil. In this case, polyethylene pipes have high resistance to corrosion and damage due to external factors such as moisture, breakage, and cracking.

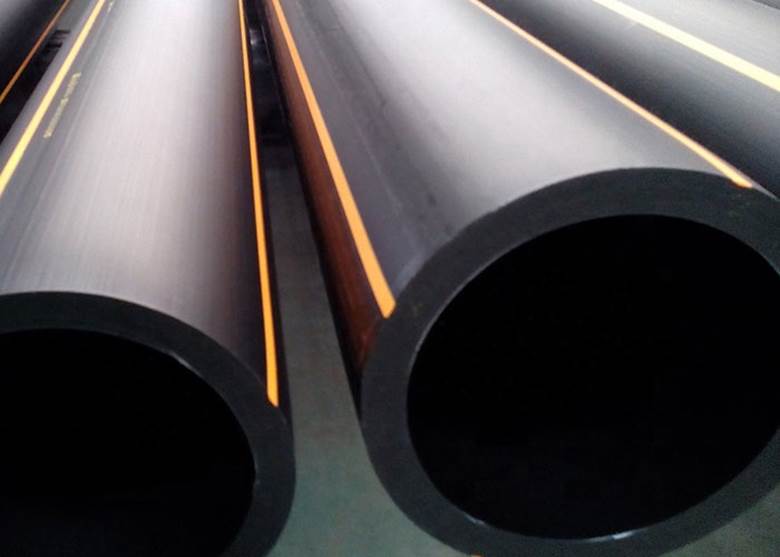

- Gas Transmission: Polyethylene pipes are used in gas transmission networks due to their lightness and flexibility. Also, if steel pipes encounter problems due to problems such as corrosion and abrasion, they can be replaced with polyethylene pipes.

- Chemical transportation: Polyethylene pipes are also used in the chemical industry to transport chemicals. These pipes are used due to their high resistance to corrosion and chemical solvents.

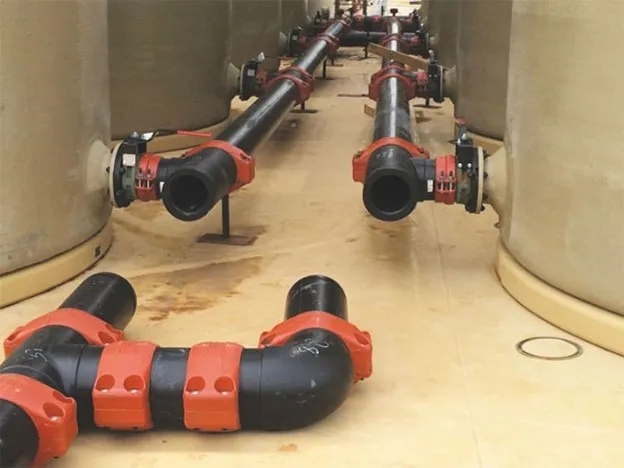

- Water transportation: Polyethylene pipes are used in water supply networks as an alternative to steel or concrete pipes due to their high resistance to corrosion and cracking.

- Other uses: Polyethylene pipes can be used in industries such as telecommunications and electricity, due to their flexibility and resistance, as a covering and protector for electrical cables, fiber optics, and sensitive telecommunications cables.

In the oil industry, polyethylene pipes are used as an alternative to metal pipes due to their many advantages. For example, one of the advantages of polyethylene pipes in the oil industry is that these pipes are used in natural gas and crude oil collection, transmission and distribution systems, oil refining processes, water and wastewater transmission, water and wastewater treatment, firefighting systems, and so on.

Polyethylene pipes are suitable for industrial applications due to their high resistance to corrosion, impact, pressure, abrasion, moisture, heat and UV rays. Also, due to their light weight and high load-bearing capacity, these pipes are an ideal choice for projects that require the transport of materials over long distances.

Due to the extraordinary properties of polyethylene raw materials

Polyethylene pipes can perform well in situations where metal pipes may fail and deteriorate. Also, due to their light weight and structure, polyethylene pipes are easy to install, transport and install, requiring less cost and time.

Another advantage of using polyethylene pipes in the oil industry is that they cost less to repair and maintain. These pipes last a long time and are less likely to break down and need to be repaired. They also require less pipe replacement due to corrosion, which ultimately saves money and time.

Overall, the use of polyethylene pipes in the oil industry is increasing due to their numerous advantages.

Other uses of polyethylene pipes in the oil industry include the transportation of fuel, gas, and water. In the oil and gas industries, polyethylene pipes are used as high-pressure transmission lines for natural gas and other industrial gases, as well as for crude oil and other product materials. Polyethylene pipes are also used to transport industrial, domestic, and drinking water.

The use of polyethylene pipes in the oil, gas and water industries, in addition to saving money and time, reduces the risk of pollution and damage to the environment. Due to their high resistance to temperature and pressure changes, polyethylene pipes can perform well in environments with harsh and varying weather conditions.

Therefore, polyethylene pipes are recognized as a suitable alternative to metal pipes in the oil, gas, and water industries due to their numerous advantages, including corrosion resistance, reduced maintenance and repair costs, shorter installation time, cost and time savings, and reduced risks to the environment.

In the oil industry, polyethylene pipes are used to transport liquids and gases in harsh and difficult environments. These pipes are used to transport materials in environments with harsh and unstable conditions due to their advantages such as lightness, flexibility, corrosion resistance, pressure resistance, impact resistance and low failure, resistance to bursting and rusting, as well as the lack of need for subsequent maintenance and repairs.

The use of polyethylene pipes in the oil industry, especially in stages such as extraction, transmission, refining and enrichment of natural gas, oil and refined products, leads to greater efficiency and reduced costs and risks. These pipes are generally used in high-pressure installations and environments that require fast and safe transfer of materials.

In the oil industry, polyethylene pipes have a longer service life than metal pipes due to their high resistance to corrosion and other factors of deterioration. Also, due to their lightness and greater flexibility, they require less transportation equipment and can be used in areas where access to heavy equipment is difficult.

The use of polyethylene pipes in the oil industry is suitable due to their high resistance to various environmental conditions, such as high and low temperatures, humidity, mechanical stresses, pressure, ground movements and earthquakes. These pipes also have high resistance to solvents and chemicals used in the oil industry.

The use of polyethylene pipes in the oil industry is also effective in reducing costs. Due to their lower weight and higher resistance to damage, they require less replacement and maintenance than metal pipes. They also require less subsequent repairs and maintenance, which reduces maintenance costs.

Overall, polyethylene pipes are used in the oil industry due to advantages such as high resistance to corrosion and damage, lightness and flexibility, resistance to various environmental conditions, reduced costs, and the need for less replacement and maintenance.