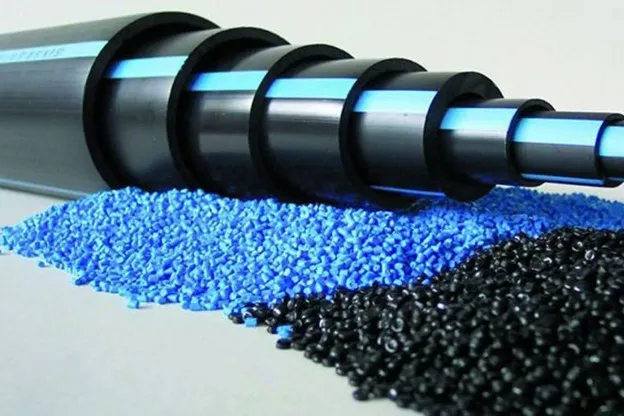

Polyethylene pipes are currently produced based on two models of polyethylene raw materials that have different standard requirements when producing the product. In this article, we will examine the differences in polyethylene pipe raw materials such as these materials.

What is the difference between PE80 and PE100 polyethylene raw materials?

PE80 and PE100 polyethylene raw materials are two different types of polyethylene that are made using different production processes and have different properties.

The raw materials of polyethylene PE80 and PE100 differ in terms of density and molecular weight, respectively.

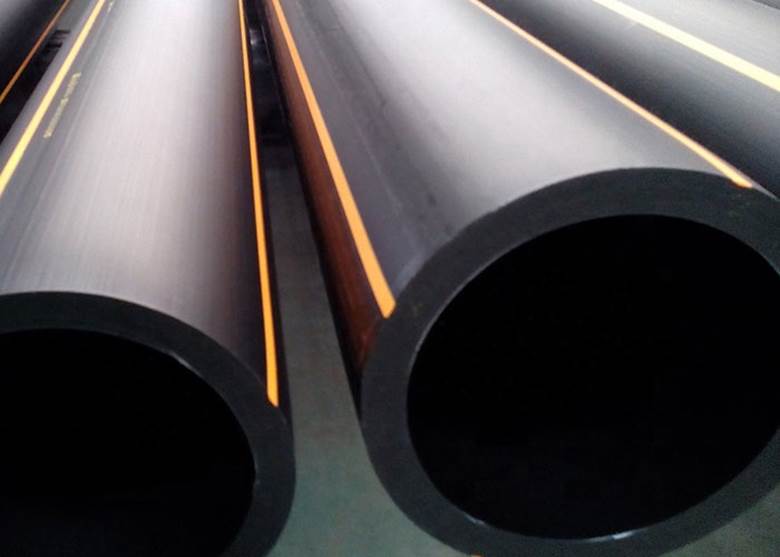

The raw material PE100 has a higher molecular weight and density than PE80, this feature makes PE100 have higher resistance to pressure and impact and as a result it is suitable for uses that require high resistance to pressure and impact such as gas, water, sewage pipelines, refineries and chemical industries. Among the pipes made from these materials, we can mention the gas polyethylene pipe.

PE80 and PE100 polyethylene are two different types of polyethylene that are made using different production processes and have different properties.

Further reading: Factors affecting the lifespan and

First of all, it can be said that PE100 has a higher molecular weight than PE80, which makes PE100 more resistant to pressure and impact, and therefore it is suitable for applications that require high resistance to pressure and impact, such as gas, water, sewage pipelines, refineries, and chemical industries.

Therefore, in applications that require higher resistance of polyethylene pipes to pressure and impact, such as gas transmission lines, it is more appropriate to use pipes made of PE100. In addition, in cases where there is a specific aqueous or chemical environment that comes into contact with the pipes, the use of PE100 is recommended due to its greater resistance to chemical corrosion.

In addition to the difference in density, other characteristics of PE80 and PE100 polyethylene materials that can make a difference in the performance of pipes made from them include:

- Modulus of elasticity: PE100 has a higher modulus of elasticity than PE80. This makes pipes made from PE100 much more resistant to pressure and impact.

- Temperature tolerance: PE100 has a higher freezing point than PE80. This makes pipes made of PE100 perform better in conditions where the pipes must be exposed to low temperatures.

- Longitudinal stability: PE100 has higher longitudinal stability than PE80. This means that pipes made from PE100 are less likely to become attached to other pipe walls and cause problems due to changes in longitudinal dimensions over time and fluctuations in temperature and pressure.

- Service life: In general, it can be said that pipes made of PE100 have a longer service life compared to PE80.

In the process of manufacturing PE100, different catalysts are used that have a higher ability to create a polymer with improved properties. The advantages of this type of polyethylene over PE80 include the following:

Further reading: What is polyethylene pipe? Types of polyethylene pipes with applications

- Higher pressure resistance: PE100 has higher pressure resistance due to its density and larger molecules. For this reason, PE100 is usually used in projects that require high pressure resistance.

- Creating larger pipes: Due to its greater resistance to pressure, PE100 is used in the manufacture of larger pipes (more than 160 mm).

- Higher fracture strength: The higher strength and hardness of PE100 compared to PE80 increases its resistance to fracture.

- Better corrosion resistance: PE100 provides higher corrosion resistance to various chemicals.

- Greater dimensional stability: Due to its higher hardness and strength, PE100 has the ability to improve dimensional stability and non-deflection in larger pipes.

- Longer service life: Due to greater resistance to corrosion and higher fracture strength, pipes made of PE100 have a longer service life.

- Higher flexibility: PE100 has greater flexibility than PE80 due to its more crystalline structure, which allows it to be used in pipes that require high flexibility.

However, in some cases PE80 is used, for example in smaller pipes (less than 110 mm) or in cases where less resistance to pressure and chemical environments is required, PE80 polyethylene raw materials are used.