Ways to identify the quality of polyethylene pipes

One of the major problems for buyers and consumers of polyethylene pipes and fittings is determining the quality of the purchased products.

Given the high cost of these products in projects, the risk of using polyethylene pipes and fittings of inappropriate quality during project operation will be very high and will cause irreparable costs to the employer and contractor

The quality of polyethylene pipes can be determined as follows:

- Use of quality materials: Examining the type of materials used in the manufacture of polyethylene pipes can indicate their quality. Pipes made with quality and standard materials generally have a longer life and higher resistance to environmental conditions.

- Checking Standards: Polyethylene pipes comply with certain standards, which are usually written on the body of the pipe or its packaging. Checking and ensuring that valid standards such as ASTM, ISO, DIN, INSO, etc. can help determine the quality of the pipe.

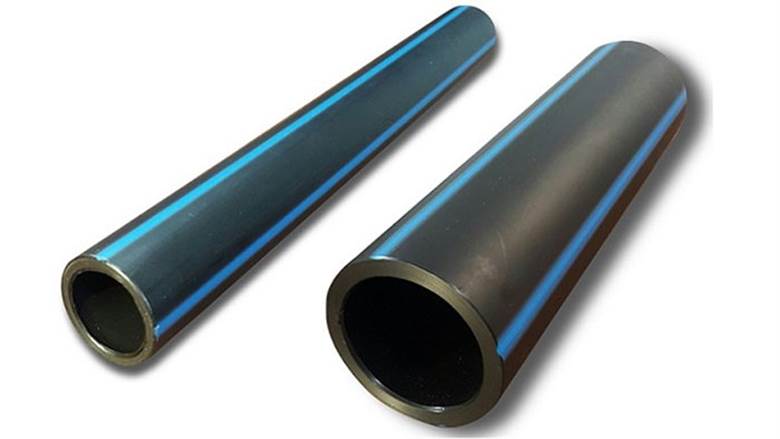

- Checking the appearance of the polyethylene pipe can indicate its quality. Specifications such as wall thickness, inner and outer diameter, smoothness and roughness of the pipe wall surface, proper marking on the pipe according to the desired standard, whether the pipe is not excessively shiny, etc. can provide important information about the quality of the pipe.

- Review of laboratory tests: Review of the physical and chemical properties of polyethylene pipes such as tensile test, melt flow index (MFR), impact resistance, pipe spread test, OIT test, heat recovery test, density, hydrostatic test, etc. help to determine the quality of polyethylene pipes.

- Certifications and Standards: Checking the certifications and standards that a polyethylene pipe has can help verify its quality. Certifications are usually issued by independent organizations and institutions and show that the product has met certain standards.

- Check the warranty: Checking the warranty terms offered by the manufacturer can also indicate the quality and trustworthiness of the polyethylene pipe manufacturing company. If a manufacturer is confident in the quality of its product, it usually offers a long-term warranty.

- Consult with experts: If you do not have enough experience in the field of polyethylene pipes, you can consult with experts or related technicians in the industry. They can guide you based on your needs and plans and provide you with tips on choosing the quality of polyethylene pipes.

Finally, to ensure the quality of polyethylene pipe, it is recommended to purchase from reputable and established suppliers and choose products that comply with industry standards and regulations.

Research and Advice: Before purchasing polyethylene pipes, you can do research on different suppliers and consult with relevant professionals and experts in the field. They can guide you in choosing the right quality and your specific needs.

In any case, when choosing polyethylene pipes, it is recommended to pay attention to the standards, technical specifications, and manufacturer recommendations and to purchase from reliable and reputable suppliers to choose the best quality for your needs.