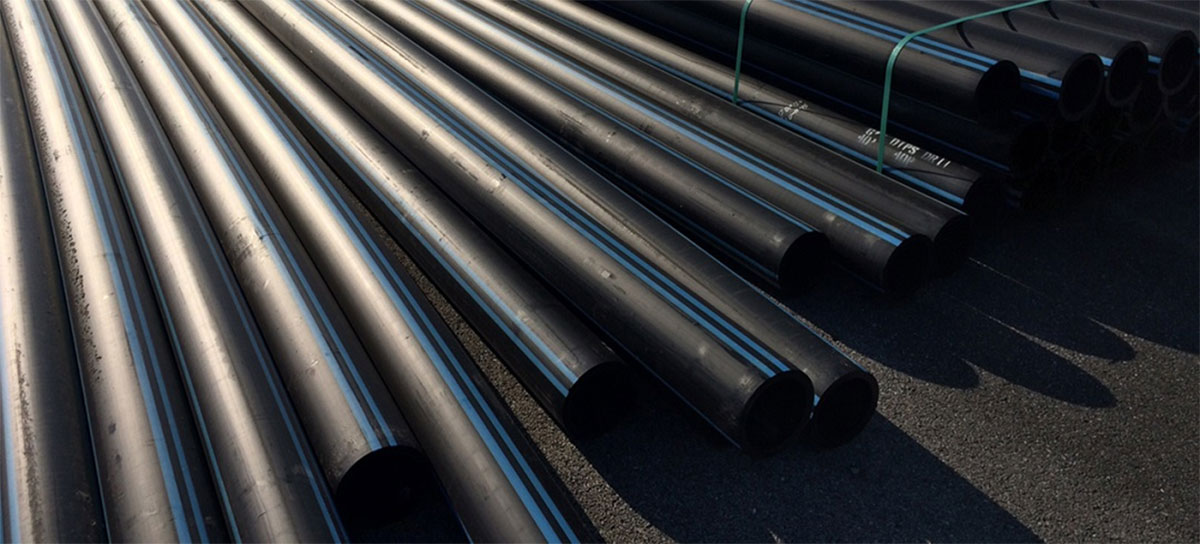

Application of polyethylene pipe in fire fighting

In complexes such as petrochemicals, oil terminals, factories and sites where the existence of a fire department is one of the requirements of that complex, it is one of the most widely used ways of transporting water and chemicals in the system. The fire department stationed in that unit uses polyethylene pipes.

The following can be mentioned among the applications of polyethylene pipes and fittings in the firefighting industry:

- Water transfer: Polyethylene pipes are well used for water transfer in fire fighting systems due to their anti-corrosion properties, resistance to chemicals and high cohesion. These pipes can transfer water from the source to the scene or to the fire fighting equipment.

- Chemical transfer: In some cases, there is a need to transfer certain chemicals in the firefighting industry. Polyethylene pipes can be used to transport these chemicals due to their high resistance to corrosion and chemical effects.

- Sprinkler systems: Sprinkler systems are used to extinguish and control fire in different places. Polyethylene pipes are used in these systems to transfer water to sprinklers and create sprinklers.

- Hydrant networks: The hydrant network includes pipes and systems that transfer water from different sources to hydrants and fire extinguishers. Polyethylene pipes can be used in hydrant networks due to their high resistance to impact, corrosion and environmental conditions.

- Fire resistance: Polyethylene pipes are fire resistant. In case of fire, these pipes can resist heat and fire to some extent and reduce the spread of heat and fire.

- No deposit formation: Polyethylene pipes prevent the formation of deposits inside the pipe due to their smooth and anti-deposit inner surface. This is an important feature in the firefighting industry, because deposits may clog the pipe and reduce the performance of the firefighting system.

- Flexibility: polyethylene pipes are made of plastic and have high flexibility. This feature allows them to transfer water and move in fire fighting systems with curvature and change of direction.

-

- Easy to install and maintain: Polyethylene pipes are very light and relatively easy to install. Also, due to their anti-corrosion properties and resistance to environmental conditions, they require less maintenance.

- Corrosion resistance: Polyethylene pipes are highly resistant to corrosion. This feature makes them suitable for use in fire fighting systems that are in contact with water and chemical solutions.

- High useful life: Polyethylene pipes have a long useful life. They have a high resistance to corrosion, rust and environmental effects, which makes them work in fire fighting systems for a long time.

- Resistance to environmental conditions: Polyethylene pipes have high resistance to environmental conditions. They can withstand changes in temperature, humidity, sunlight and other environmental factors, which is important in the firefighting industry

Comparison of polyethylene pipe with other pipes in the fire industry

Compared to metal pipes, polyethylene pipes are superior to metal pipes due to their lighter weight, easier installation, better corrosion resistance and higher impact strength. Compared to PVC pipes, polyethylene pipes have higher resistance to impact, environmental conditions and temperature changes. Also, these pipes have more flexibility and can perform better in changing the shape and direction of installing the fire fighting system.