Comparison of PVC pipe and PE pipe (polyethylene)

What is the difference between PVC and PE pipes? In which industry do they perform better? Which cost will be more economical? Why are PVC pipes used in the construction industry and polyethylene pipes are more suitable in the field of water transmission, irrigation, water supply and gas supply?

Properties and differences between PVC and PE pipes

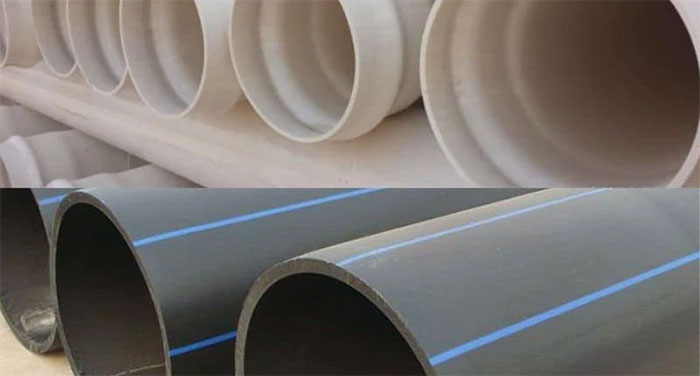

PVC (polyvinyl chloride) pipes and polyethylene (PE) pipes are two types of plastic pipes that are used in many applications.

Below is a comparison between these two types of pipes:

Materials and mechanical properties

-

- PVC: PVC pipes are made of PVC polymer. They are hard, rigid and shockproof. Due to their hard structure, they are usually of stronger pressure than polyethylene pipes.

- PE: polyethylene pipes are made of polyethylene polymer. They are flexible, soft and impact resistant. These characteristics make PE pipes withstand well and perform well in tolerating changes in volume at different temperatures.

Chemical resistance

-

- PVC: PVC pipes are well resistant to acids, alkalis, chemicals and external factors. These properties make PVC pipes suitable for applications such as water and sewage treatment, chemical and construction industries.

- PE: polyethylene pipes are also resistant to many chemicals. They usually have better corrosion and electrochemical corrosion resistance than PVC. For this reason, PE pipes are used for applications such as transporting water, gas and fuel in the oil and gas industry.

Installation and use

-

- PVC: PVC pipes are relatively simple and easy to install due to their rigid structure. They are connected by portable connectors and gluing methods.

- PE: polyethylene pipes are easier to install due to their high flexibility and light weight. They are often connected using portable push connectors.

Ultimately, the choice between PVC and polyethylene pipes depends on your specific needs, conditions and applications. Each type of pipe may be better for certain applications. For optimal use, it is better to consult with product manufacturers and experts.

continued comparison between PVC and polyethylene pipes

Corrosion resistance

-

- PVC: PVC pipes are usually less resistant to corrosion. In some special conditions, such as contact with certain chemicals, they can be corrosive.

- PE: Polyethylene pipes generally have better corrosion resistance. They have better resistance to the effects of chemical and electrochemical factors.

Flexibility

-

- PVC: PVC pipes are less flexible than polyethylene pipes. This issue may create limitations in some applications that require more flexibility.

- PE: Due to its high flexibility, polyethylene pipes are suitable for applications that require larger curves and greater flexibility. They can be quite flexible in different forms when combined with the right advice.

Cost

-

- PVC: PVC pipes are usually more economical in terms of cost. They have a more reasonable price than polyethylene pipes and are suitable for projects with a limited budget.

- PE: Polyethylene pipes are usually more expensive than PVC pipes. This may be due to superior features in some cases as well as higher production cost.

Fireproof

-

- PVC: PVC pipes have higher fire resistance and better fire resistance. For this reason, in applications that require fireproof properties, they may be a good choice.

- PE: Polyethylene pipes are less resistant to fire and may soften or crack if exposed to high heat. If fireproofing properties are important, local regulations and project safety requirements should be considered.

Size and diameter

-

- PVC: PVC pipes are usually available in a variety of sizes and diameters. They are suitable for applications that require larger or smaller diameters.

- PE: Polyethylene pipes are also available in different sizes and diameters, and can be offered in larger diameters. This capability can be possible for applications such as water and sewage transportation.

Lifetime

-

- PVC: PVC pipes have a longer lifespan under normal conditions and can usually be used for more than 50 years. However, the life time of pipes may change under the influence of various factors such as weather and environmental conditions.

Ultimately, the choice between PVC and polyethylene pipes depends on your specific needs, conditions and applications. Each type of pipe may be better for certain applications. If you need higher corrosion resistance and more flexibility, polyethylene pipes will be more suitable. But if you are looking for a more economical cost and good resistance to pressure, PVC pipes can be a good choice. In any case, it is better to consult with the manufacturers and suppliers of the products to make the right choice based on your specific needs and conditions.

In short, the advantages and challenges of polyethylene pipes compared to PVC include the following:

Advantages of polyethylene pipes

- High resistance to corrosion: Polyethylene pipes generally have better resistance to corrosion and chemical effects.

- High flexibility: Polyethylene has high flexibility and can be well flexible in changing different shapes.

- Impact resistance: polyethylene pipes have high resistance to impact and mechanical shocks.

- No effect of oxidation: polyethylene is less affected by the effect of oxidation and oxidative changes.

Challenges of polyethylene pipes

- Higher cost: Polyethylene pipes are usually more expensive than PVC pipes and have a higher production cost.

- Need for compression fittings: To install polyethylene pipes, it is necessary to use compression fittings, which may require more skill and expertise.

Ultimately, the choice between PVC and polyethylene pipes depends on your specific needs, conditions and applications. Each type of pipe may be better for certain applications. It is better to consult with the manufacturers and suppliers of the products to make the right choice based on your specific needs and conditions.