What is the difference between pe100 and pe80 polyethylene pipe

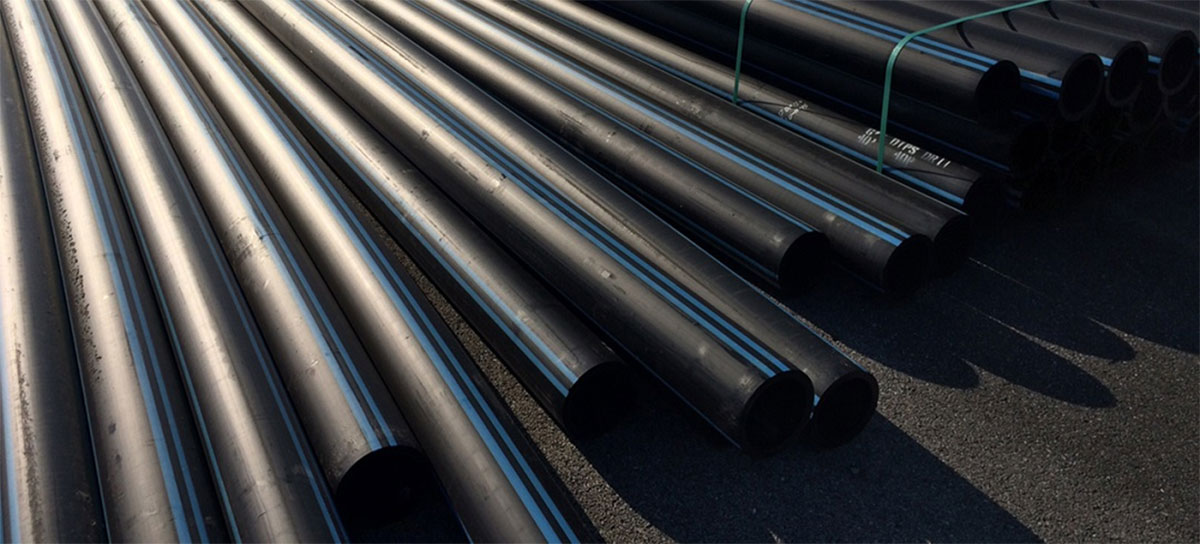

PE100 and PE80 are different grades of polyethylene (PE) used in making plastic pipes. These designations refer to the properties and performance characteristics of the material and are widely used in the plumbing industry.

PE80 polyethylene specifications

Density: PE80 has lower density compared to PE100. Density is an important factor that affects the weight and flexibility of the pipe.

Pressure rating: PE80 pipes have a lower pressure rating compared to PE100 pipes. This means that PE80 pipes are suitable for low pressure applications.

Applications: PE80 is usually used for applications where lower pressure is required, such as water distribution networks.

PE100 polyethylene specifications

Density: PE100 has a higher density than PE80. Greater density contributes to better strength and durability of the pipe.

Pressure rating: PE100 pipes have a higher pressure rating compared to PE80 pipes. This makes PE100 suitable for applications that require higher pressure resistance.

Applications: PE100 is commonly used in applications where resistance to high pressure is critical, such as gas distribution and industrial piping systems.

In short, the main difference between PE100 and PE80 polyethylene pipes is related to density, pressure rating and suitability for use. PE100 is preferred for applications where higher pressure resistance is required, while PE80 may be suitable for lower pressure applications. It is important to consider these factors when selecting the right polyethylene pipe for a particular application to ensure optimal performance and safety.

Similarities of polyethylene pipes PE100 and PE80

PE100 and PE80 polyethylene pipes have many similarities, despite the difference in density, pressure level and suitability for use. Here are some common features shared between both types:

Composition of materials

Both PE100 and PE80 pipes are made of polyethylene, a thermoplastic polymer known for its flexibility, durability and chemical resistance.

Flexibility

Both pipe types exhibit high flexibility, making them suitable for various installation methods, including trenchless technologies and situations where bending is required. It suits.

chemical resistance

Polyethylene, in general, is resistant to many chemicals and is not susceptible to corrosion and is a reliable material for transporting various fluids.

Long service life

PE100 and PE80 pipes are designed for long-term use and have a useful life that can last for decades if properly installed and maintained.

Connection methods

Both types of pipes can be connected using common methods such as butt welding, electrofusion and screw connections, which provide flexibility in the installation and repair processes. give.

Adaptability

PE100 and PE80 pipes are versatile and are used in various industries such as water supply, gas distribution, industrial piping, etc.

UV resistance

Polyethylene pipes, including PE100 and PE80, usually have good resistance to ultraviolet (UV) radiation, which is useful for outdoor applications.

While there are differences in their specific properties and applications, these common features highlight the basic characteristics of polyethylene as a material for pipes. The choice between PE100 and PE80 depends on the specific needs of the intended application, taking into account factors such as pressure rating, density and other performance criteria.