What is the useful life of polyethylene pipes?

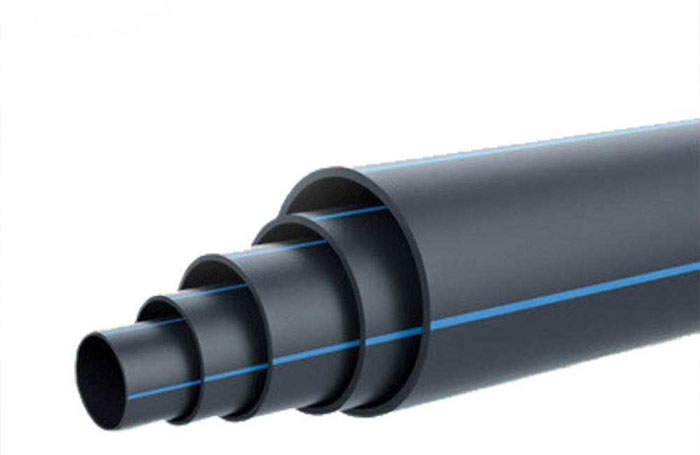

One of the main concerns of buyers and consumers of polyethylene pipes is the quality and useful life of polyethylene pipes due to the almost high cost of these pipes compared to the whole project.

The useful life of polyethylene (PE) pipes depends on various factors, including the type and quality of materials used in production, conditions of use, maintenance and installation. , and also the environment in which they are used. However, according to their physical and chemical properties, polyethylene pipes usually have a long life and can be used for 50 years or more.

To increase the useful life of polyethylene pipes, consider the following:

- Choosing quality materials: Make sure you use quality and standard polyethylene pipes. Choose reliable manufacturers and products that have received valid approvals.

- Correct installation: Polyethylene pipes must be installed correctly, following the manufacturer’s standards and instructions. Improper installation can lead to pipe failure or damage.

- Regular maintenance: Polyethylene pipes need regular maintenance and protection against harsh weather conditions. Carry out periodic inspections and repairs and necessary replacement operations.

- Prevention of corrosion and chemical damage: It is important to protect polyethylene pipes against strong chemicals, acids and alkalis. If needed, use covers and protective layers.

- Preventing contact with hard and sharp materials: Avoid contact with hard and sharp objects such as cutting tools or blades when installing, using and maintaining polyethylene pipes. This action can prevent the pipe from breaking and bursting.

- Preventing applying more force than the nominal pressure produced: Note that polyethylene pipes are sensitive to pressure and high forces. When using pipes, avoid applying pressure higher than the standard produced to prevent pipes from breaking.

- Keeping the right temperature: polyethylene pipes are sensitive to high and low temperatures. If possible, keep them at a suitable temperature such as ambient temperature (25°C) and avoid exposure to temperatures outside the permitted range. One of the best ways to increase the lifespan of polyethylene pipes and to keep polyethylene pipes away from unconventional temperatures is to bury them in the ground. It should be noted that burying polyethylene pipes in the ground prevents the penetration of ultraviolet rays from the sun and increases the useful life of the pipes. It will be polyethylene

- Regular cleaning and cleaning: Clean polyethylene pipes regularly and prevent deposits, dirt and suspended particles in them. This will maintain the quality and efficiency of the pipes.

By doing these actions and proper maintenance, you can improve the useful life of polyethylene pipes and prevent their damage and failure.

It should be noted that the most important factor in the lifetime of polyethylene pipes is the use of high-quality raw materials by the manufacturer and the production process according to the standard, Vala Polymer is one of the top manufacturers in This is the field that procures its raw materials from the best petrochemicals for the use of polyethylene raw materials and uses the best personnel and machines for the production process.