6 characteristics of gas polyethylene pipe index

One of the types of polyethylene pipes is the gas model. The use of this pipe is very popular in various industries, especially in our country, which is due to the unique characteristics of polyethylene pipes for gas supply. The main feature of gas polyethylene pipe is its high resistance to heat and fire, which has made it used in the petrochemical industry; Also, this feature allows the transfer of various gases such as liquid gas, natural gas and propane gas. In this article from Valapolymer, we will review some of the most important features of this product.

unique features of polyethylene pipes for gas supply

Polyethylene pipes are one of the most popular types of plastic pipes for transporting gas and other fluids. The reason for this popularity is their extraordinary and unique features. These pipes have created an amazing revolution in the city gas supply industry in the last few years.

They were used on a limited scale from the early 1960s to supply gas to residential areas in developed countries. But today, due to the progress in the field of making polyethylene pipes, the use of this type of pipes has expanded tremendously, due to its high quality, reliability, Health and safety of polyethylene pipe and the features of polyethylene pipe are gas supply.

Today, more than 90% of the pipes used for gas supply in America and Canada are plastic pipes, 99% of which are polyethylene pipes.</p >

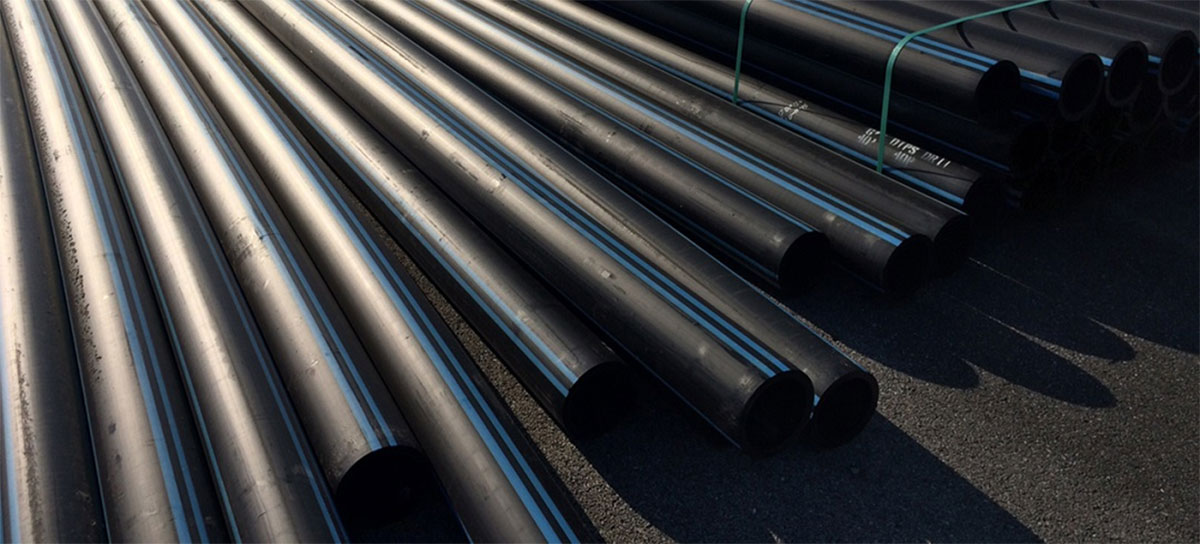

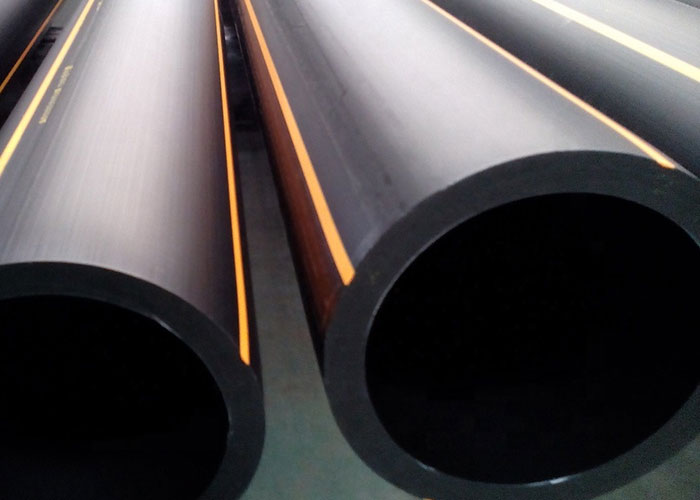

Gas polyethylene pipes are black and have a yellow line and are produced in sizes from 16 to 400 mm and above. As mentioned, the unique features of these pipes have made their use common in various industries, especially the petrochemical industry. In the following, we will describe the 6 features of the polyethylene gas supply pipe.

Polyethylene gas pipe welding ability

Obviously, pipelines cannot be integrated and it is necessary to connect pipes in areas and stages. Perhaps the most important feature of gas polyethylene pipe is the possibility of electrofusion connection. Electrofusion connection is a type of connection that is used in gas transmission pipelines and other plastic pipes carrying fluids.

Electrofusion connection happens through heating by electric current, which is the only standard type of connection due to its high safety. IGS is for gas transmission lines. With electrofusion connection, it is not possible to leak gas and other fluids. This type of connection is so reliable that it has been used in the country’s gas supply.

Another positive feature of the polyethylene pipe is the gassing of its clean connections. By using the electrofusion method, there is no fire or the need for external heating. In the electrofusion connection, heat is generated internally and through conductive lines, and the efficiency is much higher; Also, the strength created in this method will be much more and more reliable than other methods such as conventional or butt welding.

lightness and easy portability of gas polyethylene pipe

Transportation has always been one of the most expensive and challenging issues in the plumbing and piping industry. Polyethylene pipes have solved this problem with their wonderful features. The most economical feature of polyethylene gas supply pipe is its lightness and easy portability. Polyethylene pipes are sold in coils and branches, and its light weight has made the transportation process much easier and less expensive.

Ability to use gas polyethylene pipe in a mechanized way

The process of installing and using pipes is one of the most time-consuming and troublesome issues, and this problem has also been solved with the help of another feature of gasification polyethylene pipe. . The mechanization of gas polyethylene pipe makes the process of installation and operation of these pipes very convenient and easy, and the time of installation and placement is much lower than other pipes.

Read more: What features make polyethylene special?

flexibility of gas polyethylene pipe

Gasification polyethylene pipes have a very high flexibility that allows the pipes to be bent up to 25 times the diameter of the pipe. For this reason, the use of these pipes is more popular in areas where the direction or angle of the pipe needs to be changed. Also, by bending and benefiting from the flexibility of gas polyethylene pipes, it is possible to save on the consumption of excessive and additional pipes. With this characteristic feature of gas polyethylene pipes, they are the best and most suitable option for use in earthquake-prone areas.

Gas polyethylene pipe resistant to chemical corrosion

Corrosion is one of the basic problems in the pipe industry. It doesn’t matter whether the piping is of construction and urban type or petrochemical piping and oil and gas industries; But this feature of polyethylene gas supply pipe has caused this problem to be solved as well.

Gasification polyethylene pipe has three anti-corrosion layers, which is resistant to all corrosive factors such as chemicals.

These three layers of protection include the following:

- Epoxy powder coating

- Middle layer glue

- polyethylene surface layer

Epoxy powder coating is a hard and non-toxic structure that is cross-linked and weighted. High molecular weight gives two excellent chemical and mechanical anti-corrosion properties to gas polyethylene pipes.

The surface layer of polyethylene is covered with HDPE, which has a high resistance to chemicals and also It is also very effective in cathode separation.

The adhesive of the middle layer of polyethylene makes the two covering and resistant surfaces of this pipe connect to each other.

durability and longevity of gas polyethylene pipe

The longevity and durability of polyethylene pipes is very suitable for their grade and they have a better life and durability compared to other pipes. According to many reliable researches, polyethylene pipes have a very good and high rating in terms of durability and quality due to the capability of HDPE. In short, corrosion resistance, wear resistance, hydraulic performance, hardness, flexibility, long life are some of the advantages mentioned for polyethylene gas pipes.

Conclusion

In Iran and until the early 70s, metal pipes were used in most of the country’s gas distribution network. These pipes had a pressure tolerance of 60 to 250 pounds per square inch; But due to the characteristics of gas polyethylene pipes, metal pipes were quickly out of order and replaced by polyethylene pipes.

High-pressure polyethylene gas pipes caused parts of the country’s gas supply network, especially in the provinces of Tehran, Isfahan and Khorasan, to switch from metal pipes to Polyethylene pipes should be changed. According to the advantages and characteristics of polyethylene pipes and the increasing expansion of the country’s gas supply network, it is predicted that In the future, we will see a wider and wider use of polyethylene gas pipes in the urban gas supply industry. In this article from Valapolymer, we talked about the unique features of polyethylene gas pipes and we hope that for You have been useful.