Advantages and positive features of using polyethylene sewage pipes

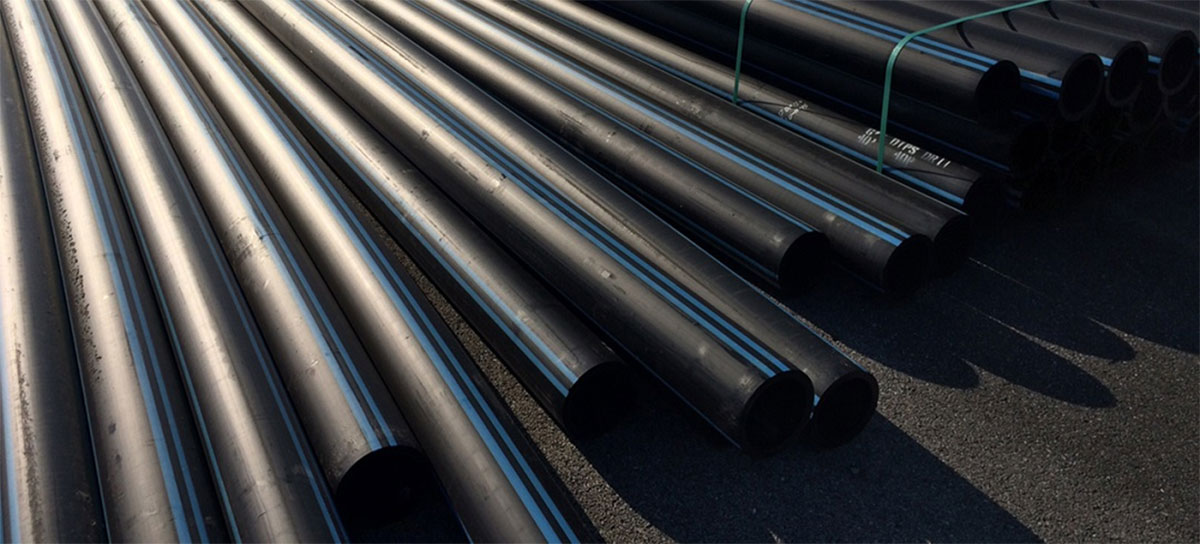

One of the new types of pipes that are widely used in industries is the polyethylene pipe, which has become very popular among craftsmen due to its features, advantages and very good applications. The materials by which these pipes are made are obtained from petroleum products, and although these materials are also used in the production of plastic products, they are mostly used in the production of pipes and fittings. Now these pipes have become a suitable replacement for metal or cast iron pipes, but what are their characteristics that have caused this? In this article, we are going to talk about the advantages of polyethylene sewage pipe. In addition, let’s talk about 7 of the most important features of polyethylene sewage pipe.

Features of polyethylene sewage pipe

In the past, when metal or cast iron pipes were used, craftsmen faced many problems and challenges, one of the most important of which was the rust and high weight of these pipes. Of course, their very short life and low durability, as well as their very difficult and difficult installation, should not be forgotten, which all made these pipes give way to plastic pipes. Today, manufacturers produce various plastic pipes, one of the most widely used of which is the polyethylene pipe, which has many advantages in transporting sewage and liquids.

One of the characteristics of polyethylene sewage pipes is that these pipes are produced in two ways, single-walled and double-walled, and the double-walled type is used in sewage. . These pipes easily allow the transfer of drinking water, and because they are non-toxic and hygienic, most industries prefer to use these types of pipes instead of other pipes.

Read more: advantages of single wall pipe

Advantages of using polyethylene pipes in sewage

Next, we are going to discuss 7 of the most important advantages of pipes polyethylene sewage, let’s mention and provide you with explanations about them.

Polyethylene pipes are highly resistant to impact and pressure

One of the best advantages of polyethylene sewer pipes is their high resistance to impact and pressure, which makes their lifespan increase and they do not need to be replaced for a long time. Only very hard and strong blows and pressures are a threat to these pipes; Otherwise, they are not easily broken or cracked, so they can easily be buried under the soil and be sure that there will be no problems.

It is good to know that various damaging factors such as the pressure from the movement of cars on the ground cannot affect these pipes and cause cracks or damage in them, provided that They should be installed at a standard and appropriate depth and be safe from the pressure of moving cars.

During the long-term use of these pipes by industries, now polyethylene pipes have proven their high resistance against damaging factors and even if a heavy and hard object falls on the ground and this If the pipes are buried at a suitable depth, you can be sure that no problem will arise for them.

High resistance of polyethylene pipes against corrosion and deposition

Other benefits that facilitates the use of polyethylene pipes in the transportation of sewage, they are resistant to corrosion and sedimentation. Different atmospheric conditions can affect pipes that have low resistance and cause corrosion in them; But because the pipes we are talking about are made of polyethylene chemicals, we can be sure that these pipes will maintain their durability against corrosion for a long time. Acidic materials cannot have a great effect on these pipes; Because this issue has been tested many times and polyethylene pipes have passed this test.

We should also say about the resistance of these pipes against sedimentation that because their inner surface is smooth and polished, water and liquids pass through them well and do not leave any residue. For this reason, there is no problem of causing deposits in the pipes. As we said, these pipes are also resistant to acid, so if the pipe gets clogged, you can easily open the pipe using acid or other substances, and remove the blockage of the pipes.

The lifespan of polyethylene sewage pipes is high

The structure of polyethylene pipes is molecular, and for this reason, they have a long life and do not lose their durability and durability for a long time. These pipes are produced in a non-decomposable way, and for this reason, they will not lose their properties if they are buried under the ground. There are different types of polyethylene pipes, one of which is called PE 100, which can last up to 15 years. This high lifespan has caused industries to switch to using polyethylene pipes to avoid additional costs.

high flexibility of polyethylene sewage pipe

Because the flexibility of polyethylene pipes is high, you can easily install them anywhere you want. High flexibility is known as one of the most important advantages of polyethylene pipes, which has made contractors not face challenges and problems during the installation of these pipes. A contractor needs pipes so that he can easily make twists and turns in them if the route is changed, and polyethylene pipes give this possibility to the contractor. Due to the very easy bending of these pipes, the contractors simply weld their two ends and also put these pipes together.

light weight and expansion properties of polyethylene sewage pipes

Polyethylene pipes are used as city and intercity sewage pipes and they must always be transported to different parts of the city, but because they are light in weight, they are suitable for contractors. They will not cause a problem. In fact, the metal or cast iron pipes that were used before were heavy and made it difficult for the contractors to transport them. Workers also had to bear a high load when unloading metal or cast iron pipes; But with polyethylene pipes, there is no longer any heavy weight and workers can easily empty and put these pipes together. These pipes also have the property of expansion, which makes them not change in shape or structure in the cold days of the year and do not change in size much in the hot days of the year.

Advantages of polyethylene sewage pipes

Simple connections and simple sealing of polyethylene sewage pipes

One of the advantages of polyethylene sewage pipes is the possibility of cutting and connecting them easily. The material of polyethylene pipes is plastic, and therefore they do not need carbon welding. You can use a simple hacksaw to cut these pipes and after touching the two ends together, weld them. If there is a leak in the pipes you welded, you can either replace the affected area or put a polyethylene bandage on it.

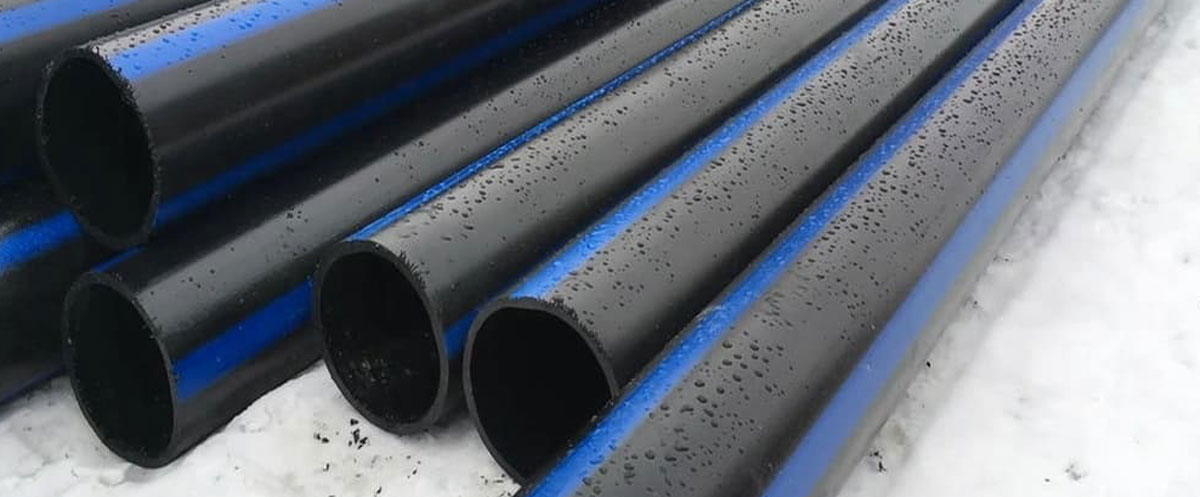

thickness of polyethylene sewage pipes

Polyethylene pipes have different thicknesses and each of them is prepared and produced for specific purposes. The thicker the polyethylene pipes, the higher their pressure tolerance.

Summary

In this article, we talked about the advantages of polyethylene sewer pipes so that you can get to know the positive features of this type of pipes. Polyethylene pipes are a good alternative to old pipes that cause many problems and challenges to install and use. By simplifying the work of technicians, these tubes help them to do their work better and more easily, as well as more accurately.

Vala Polymer sells all kinds of polyethylene sewage pipes and other products such as water supply equipment or irrigation equipment, and you can easily visit our website from the professional services of our experienced staff. benefit If you need advice on the benefits of using polyethylene pipes in sewers or want to know more about the features of this type of pipes, you can contact the numbers in the contact us section. Our experts will also help you in the field of buying these pipes and eliminate the problems and challenges of buying polyethylene pipes for you.