Features and benefits of polyethylene pipes

When choosing the type of pipes, choose a type that is reliable, long-lasting, and economical.

Single-wall polyethylene pipes are a cost-effective solution for a wide range of piping applications, including natural gas distribution, urban water and sewage, industries, marine facilities, mining, landfills, power and telecommunications channels. In addition, polyethylene pipes are efficient for aerial, underground, surface, floating and marine facilities.

According to David A. Willoughby 1 from P.O.E company is one of the main reasons for the growth of the use of plastic pipes, saving installation costs, providing workers and the necessary equipment compared to the old common pipes. If you add the potential of having lower maintenance costs and longer useful life to these things, we will understand the reason for the intense competition of polyethylene pipes in the world markets.

One of the first applications of semi-dense polyethylene pipes (MDPE 2) was natural gas distribution. In fact, many of the systems that are currently in use have been operating since 1960 with considerable success. Today, 95% of natural gas transmission pipes under 12 inches installed in America and Canada are polyethylene pipes. Polyethylene is the product of choice not only in North America, but all over the world.

For almost 50 years, polyethylene pipes have been used in potable water applications and have continuously succeeded in receiving approvals and growth in urban uses. Polyethylene pipes are quality controlled according to NSF, AWWA and ASTM standards.

Below are some of the special advantages of polyethylene pipes:

Saving life cycle costs

In urban applications, the life cycle costs of polyethylene pipes can be significantly lower than other types of pipes. The completely smooth inner surface of polyethylene pipes preserves the special properties of the flow and heat welding eliminates leaks. It has been proven that these items are a successful combination to reduce the operating costs of the system.

Leak-free and fully restrained connections

Polyethylene connection using thermal welding creates leak-free connections that are as strong as pipes or even stronger than that. The use of welding in urban applications eliminates possible leakage points that exist in other types of pipes such as PVC or iron pipes, while using common 4 male-female connections every 10 to 20 feet.

In all these male-female connections, rubber washers are used, which wear out over time and may leak, for this reason (acceptable water leakage rate) in them is 10% or more, but this rate is in polyethylene pipes with Paying attention to the possibility of using welding is relatively zero. In addition, polyethylene welded points have a self-retaining property that, while maintaining the integrity of the connections, eliminates the need for expensive shock absorbers or impact blocks.

Despite the advantages of the butt welding connection method, engineers have other ways to connect polyethylene pipes, including electrofusion and mechanical connections.

In electrofusion joints, pipes or joints are connected to each other using an electric heater embedded in them.

Sometimes mechanical connections are needed to connect the pipe to other parts such as valves or other devices. For such purposes, special connections have been created that are abundantly available to meet most practical needs.

Corrosion and resistance to chemicals

Polyethylene pipes do not rust, rot, puncture, inflate, and do not cause the growth of living organisms inside or outside the pipe. Polyethylene pipe has excellent chemical resistance and is the first choice as a material used in many aggressive chemical environments. Although polyethylene pipes are not affected by natural soil that is chemically active, but like any other pipe, if the soil is contaminated with organic solvents (oil, diesel), there may be a need for installation methods that protect the polyethylene pipe from contact. Protect with organic solvent.

It should be kept in mind that protection against liquid penetration is necessary even in the case of metal pipes and other types of pipes that are connected to each other using washers. Generally, for all piping systems that are installed in contaminated soil, it is necessary to use protective solutions during installation that guarantee the quality of the fluid to be transferred.

Flexibility and resistance to fatigue

- Polyethylene pipes at the installation site can finally bend up to a radius of about 30 times their nominal diameter. 2. Depending on the thickness of the pipe wall, this amount can be less. For example, a 12-inch polyethylene pipe can deform up to a radius of 32 feet at the installation site and in a cold state. This will eliminate many connections.

which are used for angular changes in the piping system and also make installation easier. The long-term durability of polyethylene pipes has been well researched. Polyethylene has exceptional resistance to fatigue and under the highest operating pressure, it can sustain several pressure fluctuations up to 100% above its maximum working pressure without any negative effect on long-term performance capabilities.

Seismic resistance

The toughness, 3, and flexibility of polyethylene pipes along with its other special properties, such as leak-free and fully restrained joints resulting from welding, have made it suitable for installation in active soil environments and places exposed to earthquakes.

Structural advantages

Properties such as light weight, flexibility, and fully insulated, leak-free joints, together provide cost-effective and unique installation methods not possible with other materials. In many facilities, installation methods such as horizontal directional drilling, pipe renewal using old pipe blasting, 1 slip line, 2 drilling and placing, and semi-submerged or floating pipe-hub installation can significantly facilitate construction. and save considerable time and money.

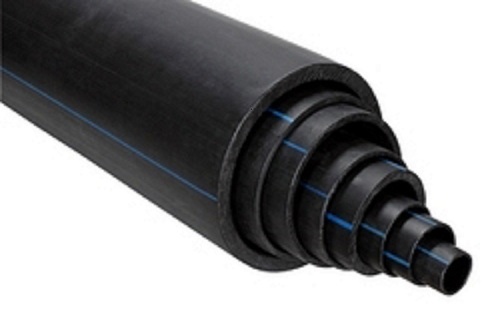

It is easier to install polyethylene piping systems with a weight of about one-eighth of steel pipes of the same size and using integrated, leak-free connections compatible with different working conditions and does not require heavy lifting equipment. Polyethylene pipes are produced in standard sizes of 50 feet or more and are wrapped in large coils in diameters of 6 inches and more. In some special diameters, coils with a length of more than 1000 meters are available.

Polyethylene pipes withstand the impact – especially in cold weather conditions where other pipes can crack and break – much better than PVC pipes. Since the butt-welded polyethylene joints are as strong as the pipe, they can be connected on the ground in a very long length and then placed directly in the trench or drilled along the well path using directional drilling. or used in the pipe reconstruction process. It should be noted that the conditions of the construction site have a significant effect on the choice of installation method.

Durability

polyethylene pipe installations are cost-effective due to the physical properties of the pipe, leak-free connections and reduced maintenance costs, and are less expensive in the long run. Polyethylene pipe industries estimate the useful life of these pipes to be between 50 and 100 years on average, provided that the piping system is designed and installed correctly and is used according to published industrial samples and the suggestions of the pipe manufacturer.

This durability and long life will save the cost of replacing these pipes. In properly designed and installed polyethylene pipe systems, there is little need for continuous maintenance. Polyethylene pipe is resistant to most common chemicals and is not susceptible to the risk of galvanic corrosion or electrolysis. Hydraulic wear – since the inner surface of the polyethylene pipe is free of any roughness, these pipes are classified as smooth pipes, the group that creates the least resistance to fluid flow.

In water applications, the Hazen-Williams C factor is equal to 150 and does not change over time. In other types of pipes, the C factor decreases drastically with the passage of time and as a result of corrosion, swelling, or the creation of living tissues, mosses, etc. Polyethylene pipes maintain their internal surface smoothness and flow capabilities without corrosion, swelling or the growth of living tissues and guarantee the hydraulic efficiency of the system during the designed life.

Temperature resistance

The common operating temperature range of polyethylene pipes in high-pressure working conditions is 0 to 140 degrees Fahrenheit. But for low-pressure working conditions and some special applications, this material can withstand much lower temperatures (up to -40 degrees Fahrenheit and below), and there are also special formulations of polyethylene that can be used at relatively higher temperatures. . Extensive tests and many applications of these pipes in very cold environments have shown that these working conditions do not have much effect on the strength and functional properties of the pipe.

Many of the polyethylene resins used in polyethylene pipes have been subjected to stress tests not only at the standard temperature of 73 degrees Fahrenheit, but also at higher temperatures such as 140 degrees Fahrenheit. Generally, polyethylene pipes retain more of their strength at high temperatures than other thermoplastic materials such as PVC.

Polyethylene materials retain approximately 50% of their strength at 73 degrees Fahrenheit at 140 degrees Fahrenheit, while PVC at 140 degrees Fahrenheit loses nearly 80% of its strength at 73 degrees Fahrenheit. As a result, polyethylene pipes can be used in many plumbing applications. It was used in a wide range of temperature changes. The features and advantages of polyethylene are very wide and some of its most important properties were explained in the previous paragraphs. In other chapters of this handbook, more detailed information about the properties and research on which these functions are obtained is provided.

Many of the functional characteristics of polyethylene pipes are the direct result of combining two important physical properties of polyethylene pipes that have been tested at different pressures. These two properties include toughness and viscoelastic behavior. Our suggestion to the reader is to keep these two features in mind while reviewing the next chapters of this guidebook.

Toughness

Toughness is the ability to change the shape of a material under the influence of stress, without breaking or eventually breaking. Also, sometimes the ability to increase the elongation strain is interpreted as toughness, and this is one of the important characteristics of polyethylene pipes, both when used above ground and underground. For example, as a result of loading from the earth’s surface, the polyethylene pipe buried in the soil changes its shape and its circular cross-section changes to an oval, and its vertical diameter decreases and its horizontal diameter increases slightly.

Increasing the horizontal diameter causes the earthen wall to pressurize the width of the pipe, this pressure prevents further deformation of the pipe and ultimately leads to the stability of the pipe. This problem finally provides the formation of soil-pipe structure and gives the ability to withstand ground vertical loads or other vertical loads to the concrete materials.

These loads can cause the failure of stronger pipes but with lower strain capability. Corrugated materials such as polyethylene used in water, natural gas, and industrial pipelines can increase local stresses from improper installation, where boulders, rubble, or tree stumps may be placed in a position to press the outer surface of the pipe,

Tolerate safely. There are many other construction conditions that may lead to effects similar to the above, for example, bending of the pipe exceeding the allowable strain, insufficient reinforcement of the pipe, unsuccessful alignment of the pipe to connect to hard structures, etc. When pipes with low toughness are subjected to such conditions of local stress increase, they do not have the proper performance of tough materials such as polyethylene.

Materials with low toughness and strainability respond differently to increased stress. Strain-sensitive materials have complex stress analysis and there is potential for stress increase in certain parts of the material. If any of these stresses exceeds the limit stated in the design, the development of cracks will begin and may lead to complete breakage of the part or product. In materials such as polyethylene pipes, they are tight

It is possible to cause more localized deformation without causing irreversible damage such as cracking. In fact, the local deformation causes a significant distribution and loss of local stress, without any harmful effect on the pipe. As a result, in general, the structural design of materials that act in the buckling mode can be done based on the average stress, and this fact greatly facilitates the design protocol. In order to guarantee sufficient toughness (strainability), special requirements have been developed, which are in the list of structural properties of materials from which toughening behavior is expected;

For example, we can mention the requirements that have been published for malleable iron and mild steel pipes. Toughness has always been considered as one of the special and inherent characteristics of polyethylene pipes, and this has been one of the main reasons for the continuous use of this material for natural gas distribution in North America for more than 30 years.

The toughness of the new generation of polyethylene pipes has been significantly improved in comparison with the old samples – which by themselves were very successful in the gas, water, sewage, industrial, marine and mining applications 50 years ago.

It is recommended to refer to Chapter 3, Material Properties, for a more detailed discussion about this unique feature of polyethylene materials, especially about the new high-performance versions of this material, and the exceptional design advantages that they have brought with them to the world of plumbing.

The viscoelastic property of viscoelasticity of polyethylene pipe is a material with a viscoelastic structure. Due to its molecular nature, polyethylene has a complex combination of fluid and elastic behavior. As a result, this material exhibits properties between metal crystals and very viscous, slow-flowing fluids. These concepts are discussed in detail in the Engineering Properties chapter of this handbook.

The viscoelastic nature of polyethylene has led to two engineering properties that are used in the design of polyethylene water piping systems:

Creep and stress damping.

Creep is a component of deformation that is defined as a time-dependent viscous flow component. Creep is also defined as the response of polyethylene to a constant load over time. When polyethylene is subjected to a constant load, it immediately undergoes a deformation which can be predicted by the elastic modulus which can be predicted from the tensile stress-strain curve. In addition to this instantaneous deformation, the material continues to deform at a slower rate under high loads, and if the load is high enough,

The material may be damaged or broken. According to industrial standards, polyethylene pipes have been designed as part of the hard materials 4, so that according to the proposed industrial samples, the deformation resulting from bearing the load, or in other words the same creep, is reduced so much that it can be ignored from the point of view of engineering.

damping

Tension is another unique feature that is the result of the viscoelastic nature of polyethylene. When polyethylene is subjected to a constant strain (deformation to a certain extent) that is maintained for some time, the load or stress caused by the deformation slowly decreases over time, although it is never completely removed.

This stress damping in response to load is very important in the design of polyethylene pipe systems. This is the response that reduces the stress in the sections of the pipe that are subjected to constant strain.

The response of polyethylene pipe systems to load, as viscoelastic materials, is time-dependent. Due to the creep and damping properties of polyethylene, the elastic modulus decreases dramatically with the passage of loading time. The moment elastic modulus for sudden events such as water hammer at 73°F is about 150,000 psi. For events that are slightly longer than sudden events, but still short-term, such as soil settlement and biological load, the short-term modulus of polyethylene at 73 degrees Fahrenheit is about 110,000 to 130,000 psi; And the apparent modulus decreases to about 20,000 to 30,000 psi in the long term. Modulus, as we will see in the coming chapters, is a key standard in the design of polyethylene piping systems.

The time-dependent response of polyethylene to load gives polyethylene a unique elasticity and resistance to sudden or relatively short-term load events. As an example, we can mention the resistance of polyethylene against the blue hammer phenomenon, which will be discussed in more detail in the next sections of this book.