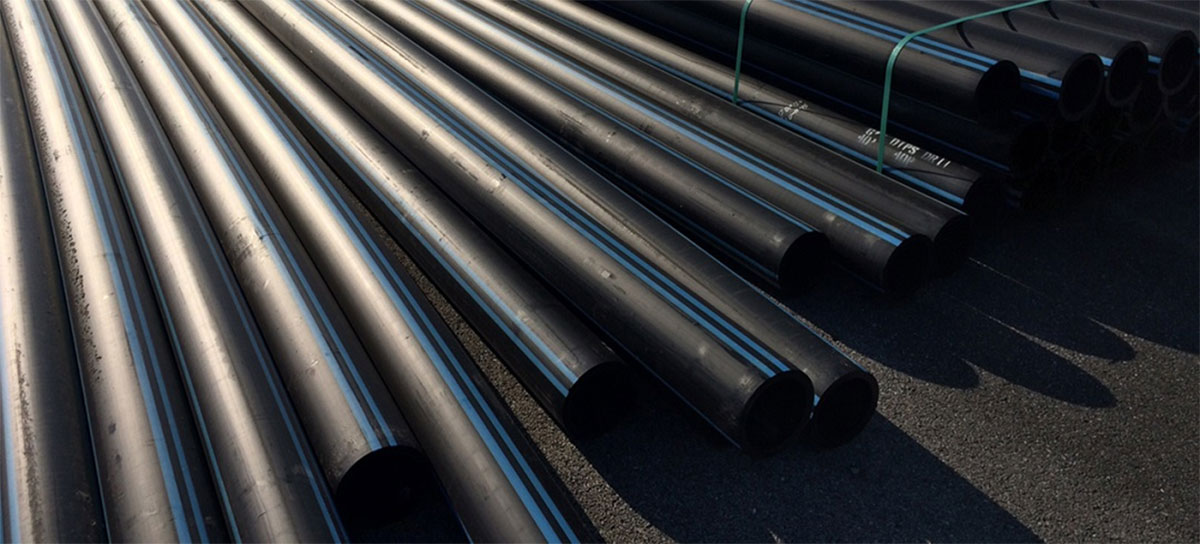

What are the signs of standard polyethylene pipe quality?

One of the concerns of every buyer is the quality of the product that he wants to pay for the quality of the mentioned product, products that are a little more complex and technical in terms of expertise, this concern is much greater. become

There are also such thoughts about polyethylene pipes, how to recognize a quality pipe

In this article, we discuss the quality factors and indicators of polyethylene pipes.

What factors does the quality of polyethylene pipes depend on?

The quality of polyethylene pipe (PE) depends on various factors, some of which are mentioned below:

- Manufacturing process: The production process of polyethylene pipe, including thermal conditions and flow rate, can affect the final quality.

- Pipe dimensions: The size and thickness of the pipe can also affect the quality of the pipe.

- Chemical stability: The resistance of polyethylene pipe to decomposition, corrosion and environmental effects can be effective.

- Quality control tests: Quality tests, such as impact and pressure testing, can affect the final quality of the pipe.

In general, to have a high quality polyethylene pipe, you must use quality raw materials, quality production process and proper quality tests.

What are the characteristics of quality polyethylene pipe?

Quality polyethylene pipe features include the following:

- Chemical resistance: High quality polyethylene pipes have excellent resistance to acids, bases, oil, water, corrosion and other environmental influences.

- Flexibility: High quality polyethylene pipes are very flexible and flexible. For this reason, they are very suitable for use in places that need to bend pipes and change direction.

- Impact resistance: High quality polyethylene pipes have very good impact resistance and do not break easily.

- Welding ability: High quality polyethylene pipes have very good welding ability and are easily welded with other parts.

- Resistance to pressure: High quality polyethylene pipes have very good resistance to pressure and work properly even at high pressures.

- Non-absorbing moisture: High-quality polyethylene pipes do not absorb moisture and, therefore, are very suitable for use in areas prone to scratches and deposits.

- Long life: High-quality polyethylene pipes have a very long life and require less replacement, which can significantly save additional costs for repairs and maintenance. be reduced.

- High fluidity: High-quality polyethylene pipes have very high fluidity and it is easy to move materials such as water, gas, and chemicals in them.

- Safety and Health: High quality polyethylene pipes have very good safety and health, and due to the lack of absorption of water and chemicals, they are suitable for use in irrigation systems, food and pharmaceutical industries, and hospitals. are.

In general, the characteristics of high-quality polyethylene pipe, including impact resistance, pressure resistance, chemical resistance, flexibility, weldability, non-moisture absorption, fluidity High, long life, safety and health, etc.

How to distinguish standard polyethylene pipe from non-standard polyethylene pipe?

Distinguishing standard polyethylene pipe from non-standard polyethylene pipe is possible in different ways. Below I mention some of these methods:

- Checking the type of materials used: In standard polyethylene pipe, high quality materials are usually used. If low-quality, recycled materials or unauthorized additives are used, the polyethylene pipe becomes non-standard.

- Checking the dimensions and thickness of the pipe: In the standard polyethylene pipe, the dimensions and thickness of the pipes are specified accurately. If the dimensions and thicknessIf the pipe deviates from the standards, the polyethylene pipe is non-standard.

- Investigation of pipe tolerance against pressure: standard polyethylene pipe has the ability to withstand different pressures. If the polyethylene pipe cannot withstand the standard amount of pressure, it is non-standard.

- Inspection of surface appearance and structure: In standard polyethylene pipe, the surface of the pipe is smooth and without lines and fractures. If the surface of the pipe is lined or broken, the polyethylene pipe is non-standard.

In general, to distinguish a standard polyethylene pipe from a non-standard polyethylene pipe, you can use the following two methods:

- Certificate Check and Standard Marks: Polyethylene pipes are produced using different standards, such as INSO, ISO and DIN standards, and to recognize the standard polyethylene pipe, you can look for the standard marks of the National Center Be certified by Iran’s National Standard Organization, Water and Soil Deputy, Ministry of Agricultural Jihad, and Food and Drug Organization to ensure the standard of the product.

- Receiving information from the manufacturer: You can distinguish between standard and non-standard polyethylene pipes by contacting the manufacturer and asking him about the technical specifications and features of the polyethylene pipe.

In general, to distinguish the standard polyethylene pipe, one should pay attention to the technical and quality characteristics of the product and, if necessary, consult with the manufacturer or related industrial experts.