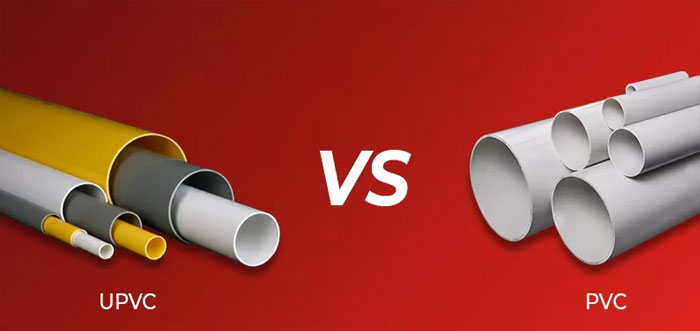

The difference between PVC and UPVC

The main difference between PVC and uPVC (Unplasticized Polyvinyl Chloride) is in the production process and their mechanical properties. The difference between each of these materials is explained below:

PVC (Polyvinyl Chloride)

- PVC is a plastic material that contains several dense units of polyvinyl chloride.

- PVC is prepared as a flexible or soft material, due to the use of a plasticizer in the production process.

- PVC is used in a number of common applications in the construction industry, including water and sewer pipes, cabling pipes and windows.

- PVC has the best performance in some applications inside the building due to its lower resistance to temperature changes and sunlight.

uPVC (Unplasticized Polyvinyl Chloride)

- uPVC is the plasticizer-free version of PVC, which means that no plasticizers are used in its production process.

- uPVC is produced as a rigid material that has higher resistance to changes in temperature and environmental conditions.

uPVC is mainly used in applications that require high resistance to pressure, corrosion, and temperature changes. such as high pressure water and sewage pipes, gas pipes, valves, windows and doors.

- uPVC is also used for marine applications, shipbuilding, and chemical industries because of its good resistance to corrosion and harsh environmental conditions.

In summary, the main difference between PVC and uPVC is in their mechanical properties. PVC is softer and more flexible and suitable for indoor applications, while uPVC is rigid and used for higher strength applications.

In short, the difference between PVC pipe and upvc pipe is as follows:

Heat resistance

- PVC: PVC has more limited heat resistance than uPVC. At high temperatures, PVC may begin to soften and deform.

- uPVC: Due to its rigid structure, uPVC has better heat resistance and shows less deformation at high temperatures.

Corrosion resistance

- PVC: PVC has less resistance to chemical corrosion and solvents. In some cases, it may change color and corrode under the influence of certain chemicals.

- uPVC: uPVC has better resistance to corrosion and chemical effects due to its structure without softener.

Mechanical resistance

- PVC: PVC is slightly weaker in terms of mechanical resistance and can be broken against impact and pressure.

- uPVC: uPVC is more resistant to pressure, impact and mechanical stress due to its more rigid structure.

Strength against sunlight

- PVC: PVC has a limited ability to resist the ultraviolet rays of the sun and may change color and shape over time.

- uPVC: uPVC has a better resistance to the UV rays of the sun and is less affected by it due to its more rigid and pure structure.

Flexibility

- PVC: PVC is more flexible than uPVC due to the use of plasticizer in the production process. This feature can be useful in some applications such as bending and adjusting ductility.

- uPVC: uPVC has a stiffer structure and is less flexible than PVC due to the lack of plasticizers used in the production process.

electrical resistance

- PVC: PVC has good electrical properties and is used as an electrical insulator. Therefore, in applications that require electrical insulation, PVC is suitable.

- uPVC: uPVC also has good electrical properties and can be used in electrical applications.

Color stability

- PVC: PVC may be affected by UV rays from sunlight and change color over time. This may be considered in applications where the appearance of the product is important.

- uPVC: uPVC has the best color resistance to UV rays due to its special structure and over timeIt has less color change.

Price

- PVC: PVC is generally less expensive than uPVC due to the use of plasticizers and an easier manufacturing process.

- uPVC: uPVC has a higher price than PVC due to the use of purer materials and a more complex production process.

Considering the above, in choosing between PVC and uPVC, consider the needs, the usage environment, the mechanical properties and the desired chemical properties.