What are the advantages, disadvantages and application of polyethylene pipe?

Polyethylene pipe or PE Pipe is a type of plastic pipe made of a material called polyethylene. Polyethylene is a thermoplastic polymer that is used in various industries due to its very suitable mechanical, chemical and physical properties. Due to their high resistance to corrosion, impact, corrosion, pressure, heat and UV rays, polyethylene pipes are suitable for conveying significant pressure in water, gas, oil, sewage, etc.

Also, polyethylene pipes are very good for use in water supply and sewage networks in mountainous areas, because they still prevent breaking with high water pressure.

use of polyethylene pipe

Polyethylene pipes are used in various industries as an alternative to traditional pipes due to their extraordinary properties. Some of the applications of these pipes are:

- Gas transmission: These pipes are used to transport natural gas, city gas, fire fighting gas and industrial gas.

- Oil and gas transportation: Polyethylene pipes are used for oil and gas transportation in oil and gas industries.

- Fazalab: These pipes are used to transport sewage in cities and villages.

- Industry: Polyethylene pipes are used in various industries, including chemical, pharmaceutical, agricultural and automotive industries.

- Building: Polyethylene pipes are used in building heating and cooling systems, fire fighting systems, and for transporting water and sewage in buildings.

Given the unique properties of polyethylene and the advantages that these pipes have compared to traditional pipes, it can be said that their use in various industries and especially in pressure transmission systems is significant. has been taken into consideration.

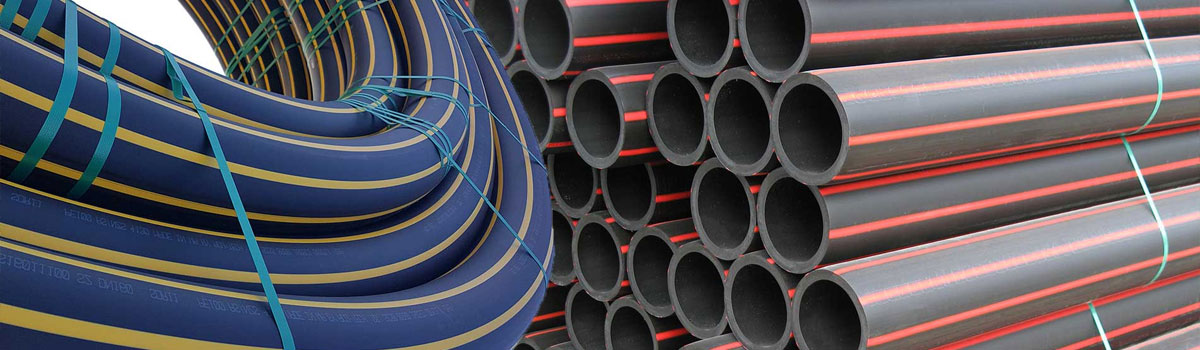

What are the types of polyethylene pipes?

Polyethylene pipes are one of the types of polymer floats and are usually used to transport fuel, gas, water, sewage, irrigation, etc. Based on the application and type of consumption, there are different types of polyethylene pipes, which are briefly mentioned below:

- High-density polyethylene pipe (HDPE): This type of pipe is produced with high density and good hardness, and is usually used to transport drinking water, sewage, natural gas, and industrial sewage.< /li>

- Medium-density polyethylene pipe (MDPE): This type of pipe is made of low-density polyethylene and is usually used to transport gas and water.

- Low-density polyethylene pipe (LDPE): This type of pipe is produced with a lower density than HDPE and is usually used to transport water and low-risk chemicals.

- Polyethylene pipe (PEX): This type of pipe is used for heating and cooling systems and has high resistance to heat and pressure.

- polyethylene polybutyl (PB) pipe: this type of pipe is used to transport gas and water and has high resistance to flame and loading.

According to the type and application of the pipe, there are different sizes and dimensions for each type.

What are the disadvantages of polyethylene pipes?

Using polyethylene pipes compared to other plumbing materials has many advantages, but along with these advantages, there are also some disadvantages that we should pay attention to. Below are some disadvantages of polyethylene pipes:

-

- Pressure drop: This type of pipe is weaker against water pressure than metal pipes such as copper and steel pipes. Therefore, to transfer water at high pressure and over long distances, you need polyethylene pipes with a larger diameter or installing a pump.

- Unsuitable for some materials: Polyethylene pipes are not suitable for transporting certain chemicals, such as benzene and toluene. In these cases, more suitable pipes such as PVC pipes should be used.

- Sensitivity to heat: Polyethylene pipes are very sensitive to temperature and at very high or low temperatures, they lose their quality and may fail or deform.

- Vulnerability to sunlight: Polyethylene pipes are sensitive to sunlight and if exposed to it, cracking and weakness in the pipe.is created.

- Leakability: Polyethylene pipes are at risk of leaking if they come into contact with sharp objects and destroy the inner surface of the pipe. Therefore, if you need to install these types of pipes, you should use appropriate and professional tools.

Polyethylene pipe raw materials

The raw materials used in the production of polyethylene pipes include high density polyethylene (HDPE), medium density polyethylene (MDPE) and polyethylene. It becomes low density (LDPE). These polymers are produced from crude oil. In the production process of polyethylene pipes, first polymer raw materials are added to each other along with additives such as antioxidant, antistatic and antifoam, and then they are formed into tubes at high temperature and high pressure, under a process called extrusion. Finally, according to the type of use, the manufactured pipes are packaged and sent to users if needed.

Lifetime of polyethylene pipes

The lifespan of polyethylene pipes depends on various features, including the type of polyethylene, conditions of use and maintenance, and their application. However, under the right conditions, polyethylene pipes can be operational for up to 50 years or more. In order to obtain the exact life of polyethylene pipes, the following points should be paid attention to:

- Pipe maintenance and usage conditions: To maintain the life of polyethylene pipes, proper maintenance and usage conditions must be ensured. For example, strong chemicals, direct sunlight and high temperature should be avoided.

- Environmental conditions: Environmental conditions such as temperature, humidity, salinity and acidity also affect the life of polyethylene pipes. For use in special conditions such as the sea environment, polyethylene pipes with higher resistance to salinity and acidity should be used.

- How to install: How to install polyethylene pipes also affects their life. In order to preserve the life of the pipes, skilled and expert installers should be used and the use of tools that may damage the pipes should be avoided.

Therefore, to determine the exact life of polyethylene pipes, one should pay attention to the above points and provide an accurate estimate of their life according to the environmental conditions and how to use them.</p >

What are the factors affecting the price of polyethylene pipes?

The price of polyethylene pipes is affected by various factors. Below we mention some of these factors:

- Type of polyethylene: The price of polyethylene pipes depends on the type of polyethylene used. Polyethylene with higher quality and better properties against corrosion, impact, heat, shock, chemicals, etc., has a higher price.

- Dimensions of the pipe: The diameter and thickness of the pipe directly affects its price. Bigger and thicker pipes are more expensive.

- Application: The type of application of the pipe also affects its price. For applications that require special features such as resistance to corrosion, chemicals, impact, heat, etc., the price of the pipe is higher.

- Market conditions: Market conditions and existing demand affect the price of the pipe. In competitive market conditions, the price of pipes decreases, and on the contrary, in high demand market conditions, the price of pipes increases.

- Production conditions: Pipe production conditions also affect its price. If the production conditions are difficult, the price of pipes will increase.

Therefore, the price of polyethylene pipes depends on several factors. Finally, to choose the best pipe according to the existing conditions, all these factors should be considered.

What are the grades of polyethylene pipe raw materials?

The grade of polyethylene pipe raw materials are divided into several categories based on their physical and chemical characteristics. Some common grades of polyethylene pipe raw materials are:

- LDPE (Low-Density Polyethylene): This grade is used to produce flexible pipes due to its low density, high flexibility, as well as the properties of resistance to breaking and tearing.

- LLDPE (Linear Low-Density Polyethylene): This grade, due to its density, gas and liquid leakage resistance, high flexibility and also high resistance to corrosion, is used for the production of industrial and electrical pipes. is used.

- HDPE (High-Density Polyethylene): This grade, due to its high resistance to pressure, corrosion and corrosion, is used for the production of high-pressure, industrial and water supply pipes.

- MDPE (Medium-Density Polyethylene): This grade, due to the special combination of HDPE and LDPE properties, isIt is used to produce pipes with significant pressure and impact resistance.

Each of the raw material grades of polyethylene pipes have special characteristics, depending on the needs used, the appropriate grade is selected for the production of polyethylene pipes.

What are the types of HDPE grades?

There are different types of HDPE grades (high density polyethylene), each of which has its own properties and uses. Some of the most common grades of HDPE are:

- PE63: This is a low density grade of HDPE commonly used for irrigation and agricultural applications. Currently, its production in petrochemicals producing heavy polyethylene extrusion is obsolete and is no longer produced

- PE 80: This is a medium density grade of HDPE used for gas and water supply pipelines.

- PE 100: This is a high-density grade of HDPE, commonly used for gas and water supply pipelines, as well as for sewage and drainage systems. will be Currently, most of the petrochemical plants in Iran and around the world have put this type of grade on their production agenda.

- PE-RT: This is a high temperature resistant grade of HDPE used for hot water and heating applications.</li >

- HDPE UV Stabilized: This is a grade of HDPE that has been stabilized against UV rays and is typically used for exterior applications such as pipes and fittings for systems. Irrigation and water supply are used.

Each of these HDPE grades has its own unique properties and characteristics that make it suitable for specific applications. Choosing the right HDPE grade depends on specific application requirements such as expected temperature, pressure, chemical resistance and environmental factors.